Structural Insulated Panels (SIPs)

At a glance

Hemsec SIPs enable the construction of more energy efficient buildings aligned with Future Homes Standards, and a significant reduction in build time. Our insulated panels are central to the development of many Modern Methods of Construction (MMC).

- Hemsec products are BBA Certified, extensively tested for Structural, Acoustic and Thermal performance, including Fire Resistance.

- Our SIPs can be used alongside a wide range of construction materials for load or non-load bearing structures.

- By combining structural and insulation properties wall thicknesses are reduced and internal space is not compromised.

Learning to build with SIPs – shaping the future of construction.

Find out why a charity is helping young disadvantaged people to enter the world of construction by teaching them how to build

with SIPs.

Applications

You can use Hemsec Structural Insulated Panels (SIPs) for all internal and external walls and roofs in domestic, industrial and commercial construction. You can manufacture an entire building using SIPs for walls, floors and roofs.

Hemsec SIPs are the best solution for applications where you need thermal efficiency. Depending on how they are used, a building manufactured using SIPs can out-perform most Passive House measures for low-energy use.

Hemsec SIPs are ideal for the following applications:

Retail

Commercial and industrial

Garden rooms and home extensions

Technical

We aim to provide you with easy to follow and relevant technical information, suited to the vast majority of applications.

Whilst we are confident the below data will help you specify, design and build your project using our Hemsec SIPs, we always encourage further conversations around your project specific requirements. This can make the most of our panels capabilities, allowing us to tailor our technical details with a project specific guarantee. Its good to talk during the early stages of your project…

Panel Data

- Cover Width:

1200mm

Dimensions & Weight:

| Nominal Panel Thickness (mm) | Weight (kg/m2) |

|---|---|

| 100 | 20.65 |

| 125 | 21.65 |

| 150 | 22.65 |

| 175 | 23.65 |

| 200 | 24.65 |

| 225 | 25.65 |

All panel thicknesses stated above are available with either 15mm or 11mm thick OSB/3 facings, and can be supplied with the foam core Filled-to-Edge or with optional 50mm edge rebates.

For further information on edge rebating, including 40mm depth options and the availability of Mini-SIP Spline jointing panels, please refer to the SIPs Technical Detailing section.

Thermal Performance:

| Nominal Panel Thickness (mm) | Thermal transmittance (U-value) W/m2K |

|---|---|

| 100 | 0.37 |

| 125 | 0.27 |

| 150 | 0.21 |

| 175 | 0.18 |

| 200 | 0.15 |

| 225 | 0.14 |

Calculated using the method required by the Building Regulations Part L2 (England & Wales) and Building Standards Part J (Scotland). Also calculated in accordance with BS EN ISO 6946:1997 and BRE report (BR443:2006)

| Foam Core Thickness (mm) | Declared Thermal Conductivity λ D (W/mK) |

|---|---|

| 70 to 80 | 0.030 |

| ≥80 to <120 | 0.029 |

| ≥120 | 0.028 |

Product Tolerances:

| Length | Width | Thickness | Squareness |

|---|---|---|---|

| -3mm | -3mm | -3mm | maximum 2mm variance |

| +3mm | +3mm | +3mm |

Insulation Core:

A rigid thermoset polyurethane insulation core by BASF, provides the following benefits:

- Closed cell.

- CFC & HCFC free.

- <5 value for global warming potential (GWP).

- Zero ozone depletion potential (ODP).

Finishes

Timber finish:

Please see our metal insulated panels page for information on steel panel finishes

Our standard SIPs panel comprises of BBA Approved 15mm Internal and 15mm External Oriented Strand Board (OSB) grade 3 facings. OSB/3 has a thermal conductivity value λ of 0.13 W/mK. Alternatively, we can produce our panels utilising BBA Approved 11mm OSB facings.

Manufactured to specification EN 13986 and EN 300:2006, OSB/3 comprises of strands of softwood bonded together using a formaldehyde free synthetic resin.

The OSB boards are responsibly sourced and are PEFC accredited; certification is available here as a

download.

Specification

-

Air Leakage:

Panel joint air-tightness = 0.01 m3/m2/hr at 50 Pa when tested to EN 12114 in accordance with BS EN 14509: 2013.

-

Acoustics:

Please refer to Hemsec SIPs BBA certificate, Section 12 – Resistance to Airborne Sound.

-

Fire:

Panel Internal and External OSB and CPB facings have Class 3 surface spread of flame to BS476: Part 7: 1987.

When Hemsec SIPs are used as part of a through-wall build up they pass the requirements of BS476 Part 21 fire resistance of load bearing walls and have achieved up to 75 minutes fire rating. Non-Load bearing walls can achieve up to a 90 minute fire rating (BS476 Part 22:1987).

-

Structural:

Loading Capacity Walls: Hemsec SIPs 125mm Wall panel. The permissible design load values for the effective span of the panels based on the results of tests undertaken and analysed in accordance with BS5268-2:2002.

Loading Capacity Roofs: Hemsec SIPs 175mm Roof panel. The permissible design load values for the effective span of the panels based on the results of tests undertaken and analysed in accordance with BS5268-2:2002.

For further technical information please refer to our BBA certificate or contact Hemsec.

-

Quality & Durability:

Hemsec SIPs are manufactured from the highest quality materials, using state of the art production equipment to rigorous quality control standards, complying with ISO9001:2008 standard, ensuring long-term reliability and service life.

The panels will have comparable durability to that of OSB/3 to BS EN 300 : 2006, therefore, provided the installation remains weathertight and damp-proof; a life of at least 60 years may be expected.

The long life expectancy of our product will reduce energy consumption of a building over its’ lifespan.

-

Guarantees & Warranties:

Warranties for SIPs construction are available from companies that offer warranty schemes and the majority of lenders are able to offer mortgages on SIPs houses. Hemsec SIPs are BBA / NHBC approved and are eligible for Premier Guarantee.

Detailing

- Rebates

Optional 40mm or 50mm rebates can be formed in our panels during manufacture, applied to any or all edges.

This is subject to the OSB facings and panel thickness, as per the below tables:

Panels with 15mm OSB/3 Facings

| Nominal Panel Thickness (mm) | 40mm Rebate Option | 50mm Rebate Option | Mini-SIP Spline panel available |

|---|---|---|---|

| 100 | ✔ | ||

| 121 | ✔ | ✔ | |

| 125 | ✔ | ✔ | |

| 150 | ✔ | ✔ | |

| 152 | ✔ | ✔ | |

| 172 | ✔ | ✔ | |

| 175 | ✔ | ✔ | |

| 200 | ✔ | ✔ | |

| 202 | ✔ | ✔ | |

| 225 | ✔ |

Panels with 11mm OSB/3 Facings

| Nominal Panel Thickness (mm) | 40mm Rebate Option | 50mm Rebate Option | Mini-SIP Spline panel available |

|---|---|---|---|

| 100 | ✔ | ✔ | |

| 125 | ✔ | ✔ | |

| 150 | ✔ | ✔ | |

| 175 | ✔ | ✔ | |

| 200 | ✔ | ✔ | |

| 225 | ✔ | ✔ |

Accreditation

Hemsec will always strive to push the limitations of our product range. We do this by testing them more thoroughly than even the most rigorous accreditation requires us to do so; underpinning our promise of quality.

The technical specifications outlined above were delivered from successful demonstrations, performed to the test standards set out by our accreditation suppliers. You can relax knowing that the business risks associated with key projects are reduced by us working directly with these bodies:

BBA

BS EN Standards

Downloads

If you can not find the information you require for this product please contact us. If you are looking to find more generic company information or another products data please browse our download section…

-

Metal Faced Ceiling Care

Button -

Metal Faced Fire Rating Matrix

Button -

Steel Matrix

Button -

Metal Faced Panel Care

Button -

Metal Faced Product Standards

Button -

Metal Faced COSHH

Button -

Hemsec Overview Brochure

Button -

ISO 9001 : 2015 Certificate

Button -

Hemsec SIPs FAQs

Button -

Controlled Environment Solutions Data Sheet

Button -

Hemsec Product Overview Brochure

Button -

Metal Faced Sustainability

Button

Education

Hemsec are producing the most relevant educational information to make your life easier.

Be you an architect, developer or installer, we can help ease you through the learning curve of our products and advance your knowledge to assist you in your day to day processes. Is there a particular topic on your mind right now? Let us know…

-

Controlled Environment Solutions – Part 3

ButtonJune 2020

-

How will buildings change post Covid-19?

ButtonMay 2020

-

How to specify Insulated Panels on your MMC project

ButtonMay 2020

-

Controlled Environment Solutions – Part 2

ButtonApril 2020

-

Controlled Environment Solutions – a new blog series

Button

Frequently Asked Questions

-

What are SIPs?

Structural Insulated Panels (SIPs) are a composite panel that can be utilised for wall and roof structures and are known as a Modern Method of Construction (MMC).

SIPs are a “Fabric-First” approach, easily integrated with a wide range of construction materials as a load or non-load bearing structure, which provide a built up - through wall panel system.

SIPs are framing, insulation, and sheathing in one pre-fabricated component.

-

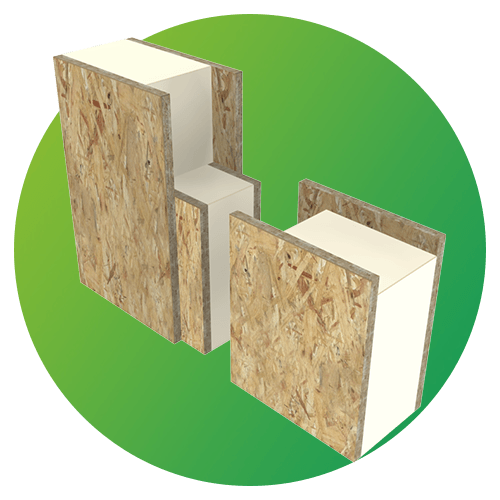

What is the build-up of a SIPs panel?

Generally SIPs are made with Oriented Strand Board (OSB) faces; however, they can also be manufactured using other sheet materials such as Plywood and Cement Particle Board (CPB).

SIPs can be manufactured with different cores including: Expanded Polystyrene (EPS), Graphite Infused Polystyrene (Neopor EPS), Polyurethane (PUR) or Polyisocyanurate (PIR).

Hemsec SIPs are manufactured utilising an injected closed cell Polyurethane - rigid foam system, sandwiched between two structurally rated skins of Orientated Strand Board (OSB/3) that can provide continuous structural integrity and superior insulation within one component.

Hemsec SIPs product ranges include: Residential (Available with 11mm or 15mm OSB) and Commercial (15mm OSB).

-

What is a U-value?

U-value is the measurement of heat flow through any given combination of materials, air layers and air spaces. The lower the U-value, the more slowly the transfer of heat in and out of a building and the better the insulating quality.

-

What type of build can SIPs be used for?

SIPs can be utilised in virtually any construction project (residential, leisure, commercial, education, retail), as structural envelopes or in-fill panels within a steel, concrete or timber frame.

-

Why choose SIPs over traditional methods?

The main benefits to building with SIPs are:

• Superior Insulation provides improved energy efficiency which reduces heating and cooling costs.

• Installation time can be reduced up to 60% against traditional construction therefore minimising overall onsite

costs due to reduced; project management, plant hire, welfare facilities and most importantly labour.

• Factory-controlled manufacturing provides a consistent and accurate engineered product allowing for easier and

precise installation.

• Offsite manufacture results in less waste on site.

• Panels can be built in to large format walls prior to site delivery therefore reducing installation time.

• Up to 7 times stronger when compared to timber frame construction.

-

What foundation should be used for a SIPs house?

Any foundation method can be used with SIPs; however, the tolerance level should be no more than +/- 5mm to allow for easy installation.

-

Would a SIPs construction be more expensive?

The initial, up-front cost of a SIP build over traditional methods i.e. timber frame or brick and block, is typically higher depending on the complexity of the design. However the savings in construction time, reduction of material waste onsite and improved energy efficiency of the building will bring significant savings, making a SIPs construction a long-term cost effective solution.

-

What are the options for external finishes?

External finishes are numerous and come down to personal preference, you can have traditional cavity and brick or stone wall, render, brick slips, timber cladding, slate, copper, zinc, stainless standing seam, etc.

-

What is the durability of SIPs

A building constructed with SIP panels will have durability comparable to other forms of construction. If the design of the structure follows best practice and the building is maintained and weather tight, a life of at least 60 years can be

expected.

-

What are the thermal, fire, acoustic and structural details of a SIP?

Full technical details of Hemsec's SIPs can be found on our quality and testing page here.

-

What certifications do I need to consider for SIPs?

When building with SIPs it is important to ensure they are high-quality. BBA Certified products are extensively tested for Structural, Acoustic and Thermal properties, including Fire Resistance which are important factors when selecting a material for your build. Many homeowners find that they cannot secure a mortgage on a SIP that doesn’t have a BBA certificate.

If you are considering using SIPs, but still have a question please contact us here.

ARE YOU READY TO TALK?

HEMSEC MANUFACTURING LTD.

Rainhill Factory

Stoney Lane, Rainhill, Prescot, Merseyside.

L35 9LL

Huyton Factory

Huyton Business Park,

Stretton Way, Liverpool

L36 6JF

CONTACT US

Tel: 0151 426 7171

Email: contact@hemsec.com

QUICK LINKS

JOIN OUR MAILING LIST

Mailing list form

We will get back to you as soon as possible.

Please try again later.